Pumps play an important role in carbon capture and storage (CCS), and choosing the most efficient pumps is key to achieving low operating costs, reducing CO2 emissions and limiting rising global temperatures.

For nearly three decades, the United Nations has convened almost all countries in the world to participate in global climate summits. The final text of COP27, the latest summit held in Sharm el-Sheikh, Egypt, includes a provision to promote low-emission energy sources. In practice, this means that a number of different technologies must be used to help reduce emissions, including carbon capture and storage (CCS) systems [1].

What is the potential of CSS?

The International Energy Association (IEA) provides an excellent overview of the potential for CO2 capture, storage and utilization [2]. It is estimated that currently capturing 45 million tonnes per year must increase to approximately 1.3 billion tonnes by 2030 to achieve a net zero emissions scenario (NZE). Approximately 35 facilities are already operational today, with more than 200 new facilities planned to be operational by 2030. However, this “only” equates to capturing 220 million tons of CO2 per year, so facilities with at least an additional billion tons of CO2 will soon be needed to meet the NZE target.

Currently, most facilities are designed to capture carbon dioxide emitted by natural gas and hydrogen processing plants. Ironically, the captured CO2 is primarily used for enhanced oil recovery (EOR). However, as oil production must be reduced in the future, most of the newly planned facilities are targeted at power plants, cement and steel industries, which cannot be fully electrified due to the nature of their raw materials. Additionally, captured CO2 should not be used for EOR but should be permanently stored underground.

How does the CO2 cleaning process work?

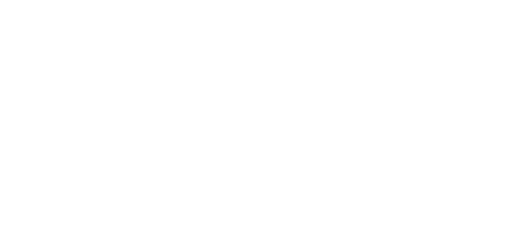

Capturing CO2 in a scrubber or absorber tower is the most common and best-known method of carbon capture. As shown in Figure 1, a liquid mixture of water and organic amines is circulated between absorber and desorber units.

Bring the inlet flue gas into direct contact with the liquid in the absorber or scrubber tower. Scrubbers are usually of the packed bed type and the total height is usually 20-40 meters (only the height of the bed is shown in the picture). If the concentration of CO2 in the flue gas is low or if high removal efficiency is required, a relatively tall tower is required.

Lean amine is fed into the top of the scrubber and enriched with CO2 by flowing downward in countercurrent to the flue gas. The first pump is used to pump the solution through the plate heat exchanger and to the desorber or stripper. By heating the liquid in the reboiler section, pure CO2 is released. A second pump is used to pump the liquid through the hot side of the plate heat exchanger and back again to the absorption tower. Additional coolers are often required to reduce evaporation of water in the absorption tower.

Calculate pump operating costs

The simulation results shown in Figure 1 are based on a number of preliminary assumptions that must be further verified and adjusted as experience with the process accumulates. However, it is interesting to try to relate the calculated pump power to the amount of CO2 captured, as we can therefore derive a preliminary estimate of the operating expenses.

It can be seen that the two pumps use a total of 1061kW of electrical power (496kW+565kW) to capture 20kg/s of pure CO2. This is equivalent to 52kJ/kg CO2 or 14kWh/ton of carbon dioxide. If we assume an electricity cost of €0.15/kWh, the operating costs for both pumps will be €2.1/ton of CO2.

As CCS units increase in popularity and capacity, selecting the most appropriate pump for a certain scrubber installation is no easy task; especially considering that 2 or 3 pumps are often installed in parallel to provide some redundancy in the scrubber system. For example, in a CCS plant capable of handling 1 million tons/year, the annual operating expenses of the pump used in the above example would be €2.1 million. At this scale, even small reductions in electricity consumption can have a significant impact on operating economics. Selecting a correctly sized pump that operates at or near the best efficiency point (BEP) is an effective way to achieve these cost reductions.

Pump specifications and selection tips

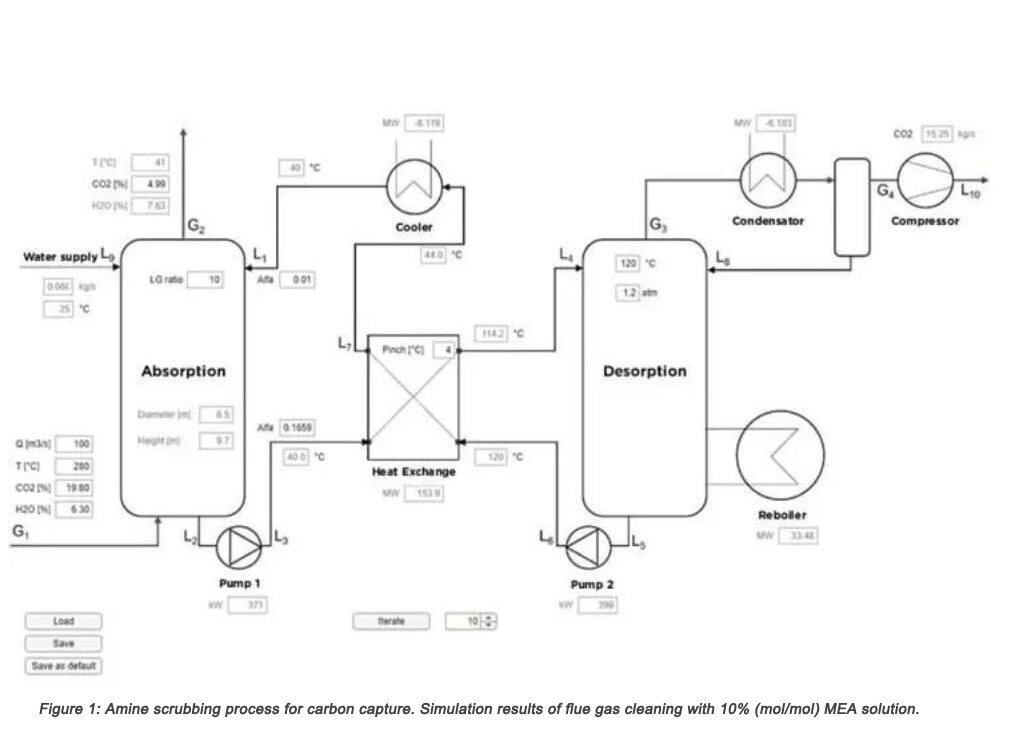

We often see that too much safety margin is added during the design phase, so in most cases the pump will run too far from its BEP (blue line on the Q-H diagram in Figure 2). In a worst-case scenario, the pump may even operate outside our recommended operating area, which is between 70% and 120% of its BEP (the area between the green dashed lines on the Q-H diagram).

It is usually best to add a safety margin to the frequency converter so that the pump can run at higher rpm in extreme situations where maximum flow and head may be required. This will save capital expenditure and operating costs as smaller pumps can be installed and more easily run at their optimum efficiency point. The pump will also run with less vibration and generate less heat, meaning there will be less excess energy that can cause damage.

Lower NPSHr values are usually required. For rich amines (pump 1 in Figure 1), the solution is almost saturated with CO2 and therefore has a relatively high vapor pressure. For a lean amine (pump 2 in Figure 1), the solution will contain very little CO2 but will be hotter, thus also resulting in a relatively high vapor pressure.

Full range of pumps and selection tools

DESMI has developed more than 60 ESL, NSL and DSL series centrifugal pumps of different sizes for the cleaning industry. They are usually designed for low NPSHr values.

Most ESL, NSL and DSL pumps are available in high-grade stainless steel or super-duplex steel (SAF2507), which we typically recommend as the MEA solution based on the latest scientific findings [3,4]. Additionally, due to the toxicity of MEA4, we recommend equipping our pumps with double Cartex seals. The sealing system can also be connected to an external barrier fluid to ensure that the gasket does not exceed its maximum temperature limit.

For projects using less toxic water and potassium carbonate solutions instead of amines (such as the Swedish BECCS@STHLM project), cheaper pump materials and our standard balanced sealing system can be used; the potassium will act as a buffer to ensure an almost neutral pH value[6].

CCS project overview

CCS projects are currently operating and developed in more than 30 countries around the world. Here’s a brief overview:

•In North America, there are about 80 projects in the United States and about 15 projects in various stages of development in Canada[2]

•China’s first project will be completed in June 2022 and is currently undergoing commissioning [2].

•In the Middle East, four facilities are operational and at least four more are in the planning stages [2].

•The EU has recently provided funding for four different projects: Kairos@C[8], BECCS@STHLM[9], K6[10] and SHARC[11].

•Three major oil companies (Shell, Equinor and Total Energy) have formed a partnership called Northern Light, which aims to store 1.5 million tons/year by mid-2024 and expand to 5 million tons/year if needed. Year[12,13]

•The French port of Dunkirk is considered a future European center for CO2 emissions, with emissions of 8.1 million tonnes/year in the first decade, and Norway’s LINCCS consortium aims to help by optimizing the entire CCS value chain and promoting new solutions. development, reducing costs by 70%[14].

•Several equipment suppliers in the maritime industry are investigating the possibility of carbon capture on ships [15, 16, 17, 18]. For example, Wärtsila and tanker operator Solvang are currently installing a pilot project to capture 80% of the carbon dioxide in exhaust gases and store it as a liquid in -35°C tanks [18]. Shipping accounts for 2.2% of the world’s carbon emissions, or about 800 million tons per year. Objectively speaking, in 2021, global energy-related carbon dioxide emissions will be 36.3 billion tons/year [19].

In conclusion

If CCS is to make a significant contribution to meeting the world’s climate goals, the technology needs to be further developed. Researchers around the world are intensively searching for liquids that are more efficient and require less energy to regenerate. However, this usually comes at the expense of reduced reactivity, so larger scrubbers must be used, or more liquid must be circulated to capture the same amount of CO2. There is no doubt that these challenges will be overcome and future CCS solutions will become more efficient, capturing more and more CO2 while using as little energy as possible.

Pumps are not the only important component of a CCS unit; other components such as compressors and reboilers consume much more electricity. However, given the number and size of future CCS plants and the fact that the success of the green transition will require us to reduce energy consumption in all industrial sectors and all aspects of human life, choosing energy-efficient pumps for CCS applications not only makes good financial sense; It is also an effective way to contribute to current and future climate goals.

References:

1. What are the key outcomes of Cop27 climate summit? | Cop27 | The Guardian

2. Carbon Capture, Utilisation and Storage – Analysis – IEA

3. J. Kittel, R. Idem, et. Al., Corrosion in MEA units for CO2 capture: Pilot plant studies; Energy Procedia

Volume 1, Issue 1, February 2009, Pages 791-797,

November 2016, Lausanne, Switzerland

https://www.sciencedirect.com/science/article/pii/S1876610209001064

4. Silje Hjelmaasa, Erlend Storheim et al, Results from MEA amine plant corrosion processes at the CO2

Technology Centre Mongstad; 13th International Conference on Greenhouse Gas Control Technologies, GHGT-13, 14-18

5. Monoethanolamine (MEA) (dow.com)

6. How it works – Beccs Stockholm

7. Selection programs | DESMI – Proven technology

8. Kairos@c (kairosatc.eu)

9. Carbon Dioxide Removal – Beccs Stockholm

10. if_pf_2022_k6_en.pdf (europa.eu)

11. Neste and the Climate, Infrastructure and Environment Executive Agency (CINEA) of the European Commission sign the EU Innovation Fund’s grant agreement for the clean hydrogen project ‘SHARC’ in Porvoo | Neste

12. What we do – Northern Lights (norlights.com)

13. Northern Lights – Equinor

14. Aker Solutions and Partners Aim to Reduce CO2 Transportation and Permanent Storage Costs by 70 Percent | Aker Solutions

15. 100% Onboard Carbon Capture May Be Possible by 2026: Value Maritime – Ship & Bunker (shipandbunker.com)

16. HMM pursues onboard carbon capture solutions with Panasia – Offshore Energy (offshore-energy.biz)

17. Alfa Laval to be a technology partner for the world´s first project to demonstrate end-to-end shipboard carbon capture at scale | Alfa Laval

18. Wärtsilä, Solvang join forces to retrofit carrier with CCS (gasworld.com)

19. Global CO2 emissions rebounded to their highest level in history in 2021 – News – IEA